For cosmetic extruded tubes with label decoration and inline shoulder moulding

Hotline : +41 840 84 84 84

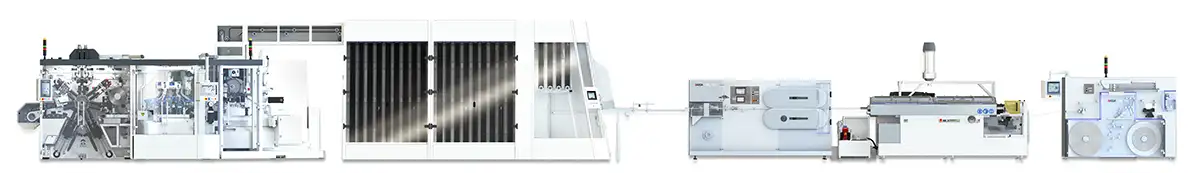

The Decoplas™ 240 tube making line is composed from right to left of a DXL 120 sleeve extruder and labeling, an accumulating store and a PTH 240 heading and CM 240 capper.

■ Key benefits

- DXL 120 operates at a faster speed of 240 t/min when producing shorter tubes.

- Most cost-effective oval tube production at 240 tubes per minute.

- Diameter down to 13.5mm to maximise usability.

- Interchgeable and standardised design.

- Tooling cost reduction.

- Lead time reduction.

- Tooling compatibility with existing machines.

- Complete automated line with Pit-Pro packer.

The Decoplas™ 240 line is a fully automated extruded cosmetic tube production line with label quality decoration capability producing up to 240 tubes per minute.

Technologies :

(Click on the icons for more information)

Machine specifications

Machine capabilities

Up to 240 tubes/min.

Tube Ø16 mm to 35 mm

Sleeve length up to 100 mm

Value-adding options

Safety seal applicator

Snap-on and screw-on cap alignment to artwork

Printed sleeve orientation

Oval tube production capability

Downstream vacuum positive transfer to packing machine

Production Data Interface to MES